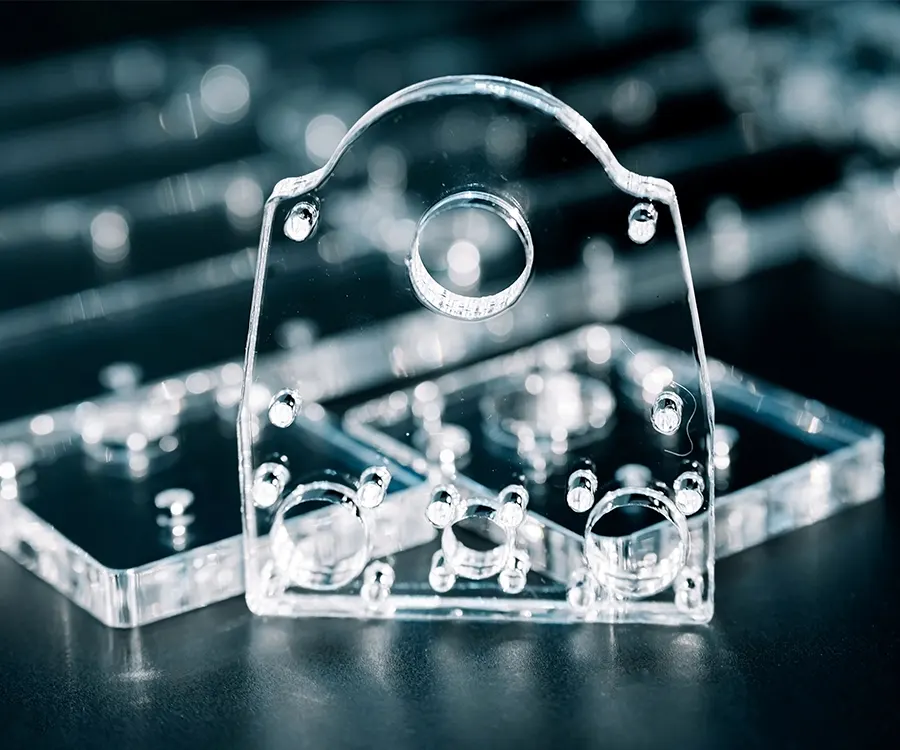

Non-Metal Laser Cutting

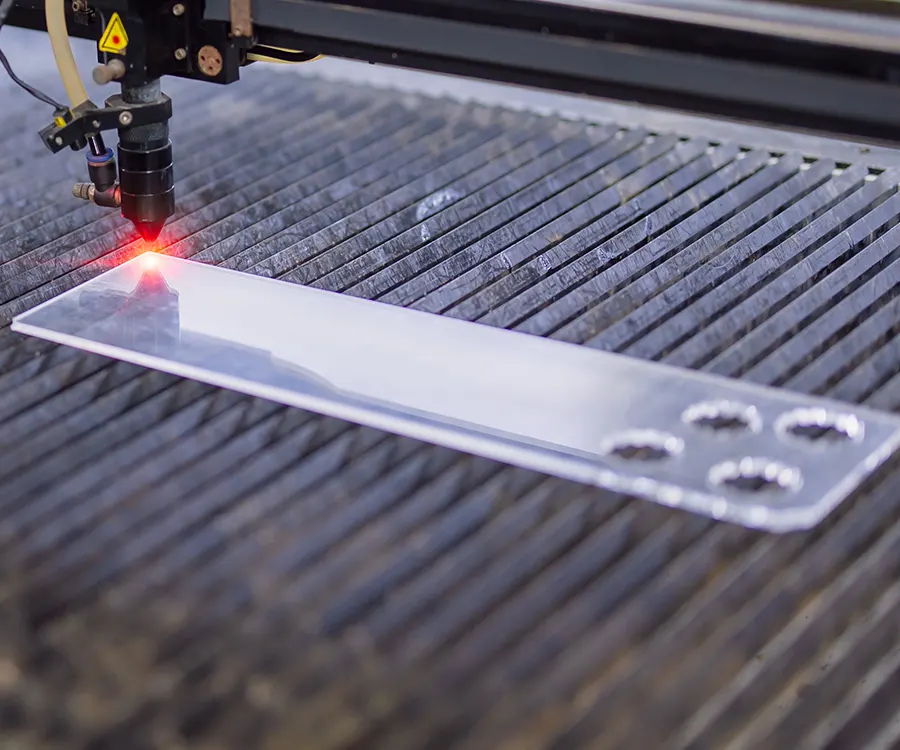

Precision Laser Cutting for Non-Metal Materials

What Is CO₂ Laser Cutting?

F.A.Q

Why should companies outsource fabrication?

Outsourcing reduces costs, overheads, and allows businesses to access specialized expertise and advanced technology. It helps companies focus on core operations, offering scalability without significant investment in machinery and labor.

What are the different types of fabrication services Smates offers?

In addition to sheet metal laser cutting, Smates offers a comprehensive suite of services tailored to meet all your metal fabrication needs. Our offerings include sheet metal bending, tube laser cutting, powder coating, welding, and 3D CAD design, all performed under one roof. This integrated approach enhances quality control, reduces lead times, and simplifies communication throughout the project lifecycle.

Whether you require OEM parts or customized solutions for companies that cannot manufacture in-house, our experienced team is dedicated to providing cost-effective services tailored to your unique requirements.

By partnering with Smates, you gain access to a wealth of expertise and resources, ensuring your projects are completed efficiently and to the highest standards.

You can check our other services by clicking here.

What materials can be cut with CO2 lasers?

What industries use CO2 laser cutting?

How can I get a quote for my laser cutting project?

You can easily get a quote for your laser cutting project by providing contacting us at: info@smates.mk with details such as product drawing, material type, thickness, quantity. Our team will quickly assess your needs and give you a competitive, no-obligation quote.

Delivery and Logistics

After production is completed, the finished products are carefully inspected, packaged, and delivered either within the local market or for international shipping. Smates works with trusted logistics partners to ensure timely and safe delivery, especially for OEMs and other B2B clients who may require export services.